Climbing Ropes

Showing 1-2 of 2 Products

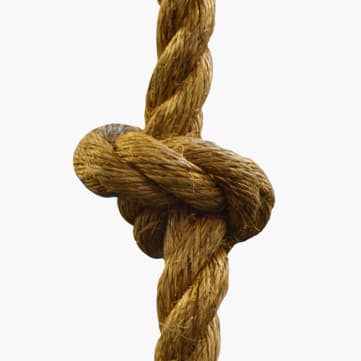

Explore Rogue's quality gym ropes built for the budding gymnast or seasoned rock climber. We stock quality manila climbing ropes, poly combo ropes-- whatever best serves your training goals. Click a rope above to see detail info, photos, and ordering info.