Rogue Kettlebell - Powder Coat

Rogue Kettlebell - Powder Coat

Gear Specs | |

| Brand | Rogue Fitness |

| Color | Black |

| Made In USA | Yes |

| Product Weight | 13LB to 88LB |

| Length | Varies by weight |

| Width | Varies by weight |

| Height | Varies by weight |

| Other Product Specs | Black Powder Coat finish |

| Handle Diameter | 13LB-18LB : 1.2" 26LB : 1.4" 35LB-88LB : 1.5" |

Product Description

The powder coat version of the Rogue Kettlebell is cast, machined, and finished in the USA and is part of our expanding line-up of quality American-made KBs.

Read More

Rogue Kettlebell - Powder Coat

The powder coat version of the Rogue Kettlebell is cast, machined, and finished in the USA and is part of our expanding line-up of quality American-made KBs.

Currently available in 12 weight increments from 9LB / 4KG up to 88LB / 40KG, each of these durable cast iron kettlebells features a Class A Powder Coat finish for superior grip, along with debossed weight indications (in both LB and KG) and Rogue branding. The 40LB / 18KG bell also meets the required specifications for the new Army Combat Fitness Test.

What Sets Rogue’s Powder Coat Kettlebells Apart:

| Material | Quality Cast Iron | These KBs are produced from two types of industrial-grade cast iron: Class 30 Grey Iron (13LB to 44LB) and Ductile Iron (53LB and above). Both are highly robust and corrosion-resistant with vibration & sound dampening properties. |

| Finish | Class A Black Powder Coat | Superior powder coating delivers a textured feel for a reliable grip + excellent resistance against scratches, chipping, and fading. |

| Gloss | 2.0 to 2.5 GU Rating | Creates a low gloss, traditional matte look. |

This kettlebell line is the product of a joint effort between Rogue and a group of uniquely qualified independent businesses, including two of the leading metal casting foundries in the Midwest: OSCO Industries (Portsmouth, Ohio) and Cadillac Casting, Inc. (Cadillac, Michigan). The machining and powder coating of each kettlebell is also handled by experienced specialists, resulting in a durable, precision-made, high-performance product.

For additional American-made Rogue KBs, see the ductile iron Rogue Kettlebell - E-Coat..

Note: *Due to the casting process, cast products may have minor variances in the finish.

Gear Specs

Specifications:

- Made In USA

- Cast by OSCO Industries and Cadillac Casting, Inc

- Material: Class 30 Grey Iron (9LB-44LB), Ductile Iron (53LB+)

- Available Weight Increments: 9LB (4KG), 13LB (6KG), 18LB (8KG), 26LB (12KG), 35LB (16KG), 40LB (18KG), 44LB (20KG), 53LB (24KG), 62LB (28KG), 70LB (32KG), 80LB (36KG), and 88LB (40KG)

- Bell Dimensions: Vary By Weight

- Finish: Black Powder Coat - Class A

- Handle Diameter: 1.2" (9LB-18LB), 1.4" (26LB), 1.5” (35LB-88LB)

- Flat Base

- Debossed Weight Indications and Rogue branding

- Meets Required Specifications for US Army Combat Fitness Test (40LB / 18KB)

See More: Kettlebells Available from Rogue

Shipping

Rogue Fast Shipping

The Rogue Shipping System allows you to track your order from the time you place it to the time it hits your door. Order today, track today.

Cast by OSCO Industries...

OSCO Industries has operated foundries in South-Central Ohio for nearly 150 years. Serving a wide variety of industrial markets from air conditioning and refrigeration to automotive, power-transmission equipment, and pumps & valves, the team at OSCO were well equipped, ready and willing to make an American kettlebell of the highest standard, using Class 30 Grey Iron to produce our 9LB through 44LB increments. This is the same highly durable cast iron often found in industrial strength frying pans, manhole covers, diesel engine blocks, gearboxes, and machine tool parts.

...And Cast In Michigan by Cadillac Casting

The town of Cadillac, Michigan has a long and storied manufacturing history, and Cadillac Casting, Inc., has been a big part of it, designing and producing a wide variety of complex and safety-critical components for the automotive industry and other industrial clients since the 1920s. This reputable, privately owned foundry employs 400 highly skilled workers, who seamlessly took on the job of producing the 53LB through 88LB KBs for our powder coat line, as well as our complete E-Coat line. Cadillac uses Ductile Iron, aka nodular cast iron, which contains strong graphite nodules that give it a superior tensile strength and corrosion resistance well suited to automotive components, wheels, gearboxes, machine frames, and, of course, kettlebells.

Precision Machining

After casting, each KB is CNC-machined to precisely cut and smooth over the flat bottom and ensure a weight tolerance of +3% / -0% (based on the KG measurement). This machining is handled by Cadillac Casting (in Michigan) and MAKO Finished Products (in Ohio).

Powder Coat Finish = Enhanced Grip

Next, the kettlebells are sent for powder coating, with the work handled by two more Midwest leaders: Greenfield Products (Greenfield, Ohio) and CRM, Inc. (Traverse City, MI). These companies have nearly 100 years combined experience, specializing in advanced finishing work for the appliance, automotive, and marine equipment industries. Their advanced powder coating systems enable the proper conditioning of materials for achieving Class A specifications (with maximum inspection time and minimum allowable defects). This textured powder coat finish doesn’t just look good; it delivers an enhanced grip, consistent feel, and scratch/chip resistance beyond that of most traditional kettlebells on the market. With all KB sizes, the finish has a matte black, low gloss appearance with Rogue branding + “Made in the USA” on one side and debossed weight indications in both KG & LB on the other.

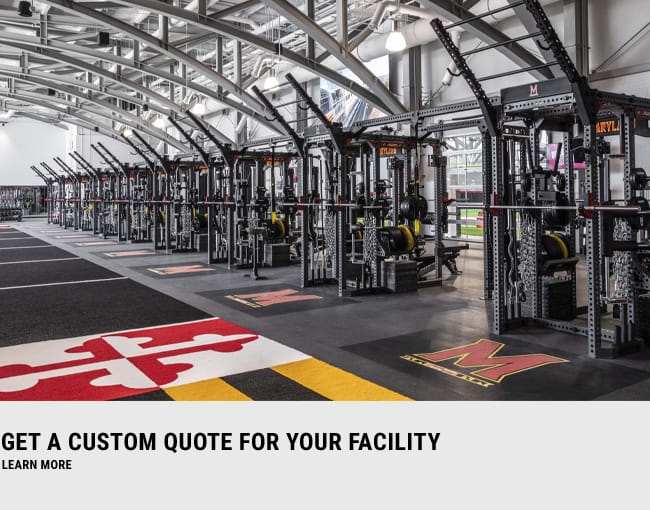

Wide Selection

Whether you’re purchasing a single set of KBs for your garage gym or outfitting a large facility, this first series of Rogue Powder Coat Kettlebells is available in a wide range of weight increments to suit most goals—from lightweight beginner bells (starting at 9LB / 4KG) up to 53 LBS / 24 KG. The handle diameters, noted below, range from 1.2” to 1.5”. Please Note: The actual weight of each kettlebell is designed to match the KG weight. So for example, the 35LB Rogue Kettlebell is actually spec'd to weigh exactly 16KG with a +3% /- 0% tolerance.

Rogue E-Coat Kettlebell Handle Diameters:

9LB - 18LB: 1.2"

26LB: 1.4"

35LB - 88LB: 1.5"

Approved for ACFT

The 40LB Rogue Kettlebell meets all requirements for use with the United States Army’s Combat Fitness Test, a 6-event readiness assessment that replaced the previous 3-event Army Physical Fitness Test in 2020. The grueling new ACFT is neutral across all genders and age groups, and includes a strength deadlift, standing power throw, hand-release push-ups, sprint/drag/carry, leg tuck,and a 2-mile run.